CNC Horizontalis Gravis Roughing Machining Center HB Series

Features

Mensam Type Horizontalis Machining Center

X/Z axis linearis guideway,Y axis est dux durus.

Arca fusi plena est structuris calceis et torques magnis.

Summus sumptus faciendis, apta ad machinis aspera et semi- perficiendum.

Movens Columna Gravis Roughing Horizontalis Machining Center

Agmina columnae movens.

X / Z axis lineae lineae est, Y axis upgraded ad tramitem durum, Y-axis columnae rigorem amplificationem.

Gearbox upgrade, efficientia secans valde melior.

Phasellus ad novum scuti genus.

Fusum celeritas ad 4500 rpm upgraded est.

Area Type Horizontalis Machining Center (graves roughing machine)

Grave officium secandum et grave, instrumentum acutum ad asperandum et semifiniendum, durabile.

Tabulatum stan- tium, capacitas magna oneris afferens.

Revolutiones plenae calces 10-3000, torque plus quam 1000N.m attingere possunt.

Ram extendere potest 700mm ad expediendas.

Instrumentum acutum ad rudendum et semi-finiendum automobile formas. .

Aureus motor motor augetur 30-37kw, calces augetur, habena structura optimized est, et vis secans valde aucta est.

Technical Specifications

| Item | H B 1 7 1 2 ( Worktabletype) | H B 1 8 1 2 (Movere columna genus) | HB2516/HB3016/ HB3020(Genus pavimento-stantem) | |

| Processus range | ||||

| X-axis peregrinatione | mm | MDCC (operarium movet dextra laevaque) | MDCCC (operarium movet dextra) | 2500/3000/3000 (columna dextra laevaque movet) |

| Y-axis peregrinatione | mm | 1200 (fusum arca sursum deorsumque movens) | 1200 (fusum arca sursum deorsumque movens) | 1600/1600/2000 (fusum sursum et deorsum arca movet) |

| Z-axis peregrinatione | mm | 700; | 800 (columna progrediens et retrorsum) | 700 (Aries ante et retro; |

| Fusum centrum ad mensam | mm | 0-1200 | 130-1330 | 100-1700/100-1700/100-2100 |

| Fusum est finis facie ad mensam centrum | mm | 150-850 | 200-1000 | 200 |

| Dux plenas blasphemiæ genus |

| XZ axis linearis dux/Y axis ferreus | XZ axis linearis dux/Y axis ferreus | |

| Worktable | ||||

| Operabilia dimensiones | mm | MDCC*850 | 1600* 1000 | 2500* 1550/3000* 1550/3000* 1550 |

| Worktable onus afferentem | kg | 5000 | 8000 | 30000 |

| Specificationes socors-T (latitudine * spatio) | mm | 18*150 | 22* 150 | 22*200 |

| Fusum | ||||

| Drivemodus |

| Plena calces | Plena calces | Plena calces |

| Maximam celeritatem | rpm | 3000 | 4500 | 3000 |

| Fusum potentiae | kW | 15/18.5 | 15/18.5 | 30/37 |

| Maximum fusum torque | Nm | 286/472 | 473/894 | 498/748 |

| Fusum cereus / pin viverra |

| BT50-45° | BT50-45° | BT50-45° |

| Coegi feed | ||||

| Maxime celeri motus celeritas X/Y/Z * | m/min | 10/10/10 | 10/10/10 | 10/10/10 |

| Maximum celeritatem secans X / Y / Z * | m/min. | 6/6/6 | 6/6/6 | 6/6/6 |

| Minimam resolutionem | mm | 0.001 | 0.001 | 0.001 |

| Accuracy (explication vexillum GB/T19362.1-2003) | ||||

| X / Y / Z accurate Positioning | mm | 0.03 | 0.03 | 0.05 |

| X/Y/Z Repeatability | mm | 0.02 | 0.02 | 0.03 |

| alii | ||||

| CNC system |

| FANUC Oi MF(5) | FANUC Oi MF(5) | Fanuc Oi MF (1) |

| potentia | kW | 60 | 60 | 75 |

| Machina altitudo | mm | 3300 | 3300 | 4200/4200/4700 |

| Area foolr (latitudinem * width) | mm | 6600*4300 | 5600*4500 | 6000*4500/7000*4500/7000*4500 |

| Apparatus pondus (proxime). | kg | 15000 | 20000 | 25T/28T/32T |

Configurationis Intro

(1) FANUC 0i-MF (1)

Latin FANUC Oi-MF Una CNC Systema, princeps processus effectus princeps rate operans, alta facilitas usuum. Eodem tempore SIEMENS/Mitsubishi CNC systema secundum necessitates eligi potest.

(2) Spindle

BT50 fusum est magna celeritate, altae efficientiae, altae torques processus notae, obviam processui necessitatibus variae materiae typicae.

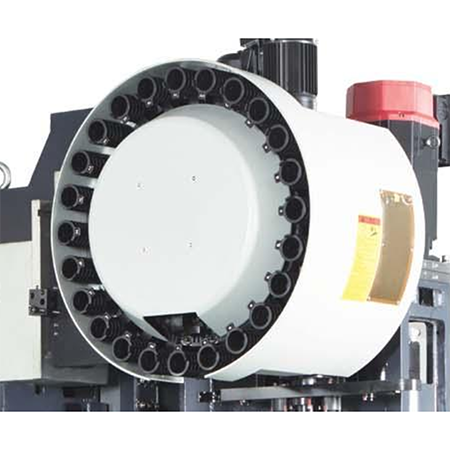

(3) Instrumentum Magazine

Vexillum 24T instrumentum emporium instrui potest cum 40/60T instrumento emporium secundum actualem processus necessitates obviam clientium variis missionibus secandis.