E30 CNC Cylindrica Molendum Machina For Cutter Tools

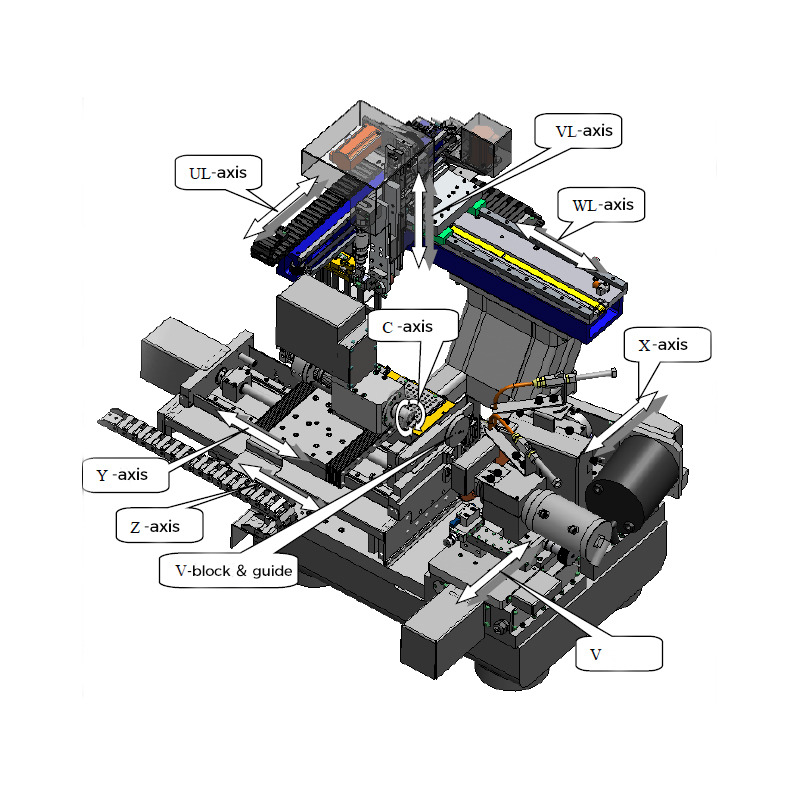

Praecipua structura machinae

application scope

Applicationem range: milling circumdatos, exercitio frenum, reamer et variae partes summus praecisio processus.

Processus range: diameter productorum processuum: Φ3~Φ20mm, longitudo productorum processuum: 120mm (automatic), 330mm (manuale).

Processus notae: simultaneus stridor rotis subtilis et crassus stridor duplex, unus temporis processus et formans.

Apparatus introductio

1. Lectus structurae;

2. Sheet metal of the whole machine: tota machina structuram plene inclusam habet, et principale corpus ab exteriore velamine ad vibrationem vitandam separatur.

3. Imperium systema: NEWCON

4. Principium qr;

• X-axis (mechanismus rotae crassus stridor): cognosce motum reciprocum rotae stridoris in X-axis directionis;

• V-axis (mechanismus rotae subtilis stridor): cognosce motum reciprocum rotae stridoris in V-axis directionis;

• Y-axis (Y-axis mechanismum pascens): cognosce reciprocum motum factibilis in directum Y-axis;

• C axis (mechanismus gyrationis caput operans): animadverto motum gyratorium capitis laborantis in directione axis C:;

axis UL, VL axis et axis WL (manipulator ligo et mechanismus locus): cognoscunt motum reciprocum tractatoris in directionibus horizontali et verticalibus;

• Rector rotae et V-obstructionum subsidium: Auxiliaris ad complementum machinæ.

1. Partes motrices: X axis, V axis, Y axis, WL axis, UL axis, VL axis, mechanismus rota, bracchium mechanismus, hysteresis temperatio mechanismus

2. Workpiece fusum: Chuangyun auto facta fusum

3. Fusum molendum: Xiamen Tungsten Motor

4. Lubricatio totius machinae: papillae olei singulis axi reservatae et regulariter lubricae

5. Modus Pascendi: Tres axis manipulator pascens

Specificationes technicae

| modus imperium | Bullae externae, velum tange | |

| Modum monstrare | Tactus screen, monens lux | |

| refrigerandum modum | Oleum frigidior Thracam | |

| modum translationis | Hydraulica, pneumatica, motor servo | |

| potentia copia | AC 3×380V 50Hz | |

| Maxime summa potentia | 25KW | |

| Dimensiones | 2152×1838×2614 mm | |

| crassa pondus | 3050kg | |

| Frigus pressura oleum | 0.6~0.8MPa | |

| barometric pressura | Totalis via pressura: 5 ~ 6Bar | |

| Chuck aeris pressura: 2 ~ 3Bar | ||

| Gubernator rota caeli pressura: 2~2.5Bar | ||

| Gripper caeli semita pressura: 1.5~ 4Bar | ||

| Brachium caeli pressura: 5~6Bar | ||

| Optical scale purgatio caeli pressura: 0.6~ 0.7Bar | ||

| Manipulator parametri | ||

| UL axis | Travel | 450mm |

| Repeatability | 0.02mm | |

| Maxime operating celeritate | 15000mm/min | |

| VL axis | Travel | 100mm |

| Repeatability | 0.02mm | |

| Maxime operating celeritate | 15000mm/min | |

| WL axis | Travel | 540mm |

| Repeatability | 0.02mm | |

| Maxime operating celeritate | 15000mm/min | |

| Processus axis parametri | ||

| Y axis | Travel | 350mm |

| Consilium minimum Sagaciter | 0.0001mm | |

| X axis | Travel | 35mm |

| Consilium minimum Sagaciter | 0.0001mm | |

| V axis | Travel | 35mm |

| Consilium minimum Sagaciter | 0.0001mm | |

| Rector rotae | Accuratio gyrationis: | ≤0.010mm |

| Caput operantes (C axis) | Motor Power | 1.57Kw |

| Celeritas rotating | ≤2000rpm | |

| Runout accuracy | ≤0.002mm | |

| minimum resolutio | 0.0001° | |

| Fusum rota aspera stridor | Motor Power | 8.5KW |

| Celeritas rotating | ≤5000rpm | |

| Runout accuracy | ≤0.002mm | |

| dynamic statera | ≤G0.4 | |

| Denique stridor rota fusi | Motor Power | 1.4KW |

| Celeritas rotating | ≤7950rpm | |

| Runout accuracy | ≤0.002mm | |

| dynamic statera | ≤G0.4 | |

| stridor parametri |

|

|

| Paul exemplum | W20 | |

| Crassum stridor rota diameter | Ø250mm | |

| Denique stridor rotae diametri | Ø150mm | |

| Workpiece Shank Diameter | 3-Ø12mm (automatic) / 3-Ø20mm (manual) | |

| Workpiece molendum dolor | 0.08 - 20mm | |

| workpiece longitudo | 120mm(automatic) / 350mm(manual) | |

| Maxime processus longitudinem workpiece | 330mm | |

| Processus diametri exterioris runout | ≤0.003mm | |

| Longitudo machining accuracy | ±0.1mm | |

| Angulus machining accuracy | ≤0.3° | |

| specie accurate | ≤Ra0.4 (stridor metam) | |

Configuratione vexillum album

| 10 | CNC system | NEWC0N | 1 |

| 20 | servo motricium | NEWC0N | 8 |

| 30 | server Coegi | NEWC0N | 4 |

| 40 | Operatio panel / rota manu | NEWC0N | 1 |

| 50 | Magna cura opus capitis moduli | GESAC | 1 |

| 60 | Summus praecisionem electrica fusum (1.4KW) | GESAC | 1 |

| 70 | Magna cura motoris (7.1KW) | GESAC | 1 |

| 80 | Princeps praecisione mechanica Spindle | GESAC | 1 |

| 90 | Subtilitas rail | Schneeberger | 10 |

| 100 | Subtilitas Crossed Rollerus via linearis | Schneeberger | 4 |

| 110 | Subtilitas Ball Screw | NSK | 4 |

| 120 | Operatio et processus simulationis programmata (gradus differentiae, sphaerici, etc.) | GESAC | 1 |

| 130 | Inverter | GESAC | 1 |

| 140 | Inverter | GESAC | 1 |

| 150 | tactus screen | 19寸ELO | 1 |

| 160 | Machina instrumentum salutis ostium clausum fabrica | Jinzhong | 1 |

| 170 | sensorem | Baumer | 3 |

| 180 | influunt sensorem | Yifumen | 1 |

| 190 | Electrical components | Schneider | 1 |

| 200 | Pneumatica Components | CKD | 1 |

| 210 | Filum et cable | ComCab | 1 |

| 220 | Eculeo aer Conditioner | GESAC | 1 |

| 230 | Subtilitas pressura rota 92x8 | GESAC | 1 |

| 240 | Subtilitas pressura rota 92x15 | GESAC | 1 |

| 250 | Chuck W20 D4 | GESAC | 1 |

| 260 | Ipsumque D4 | GESAC | 3 |

| 260 | Summus cura matching V-obstructionum (3-6) * 10 | GESAC | 1 |

| 280 | Alta cura stridor rotae LABIUM (velox genus mutatio) | GESAC | 2 |

| 290 | Plena paro digitorum tractatori | GESAC | 1 |

Apparatus characteres

7 CNC axes, 4 CNC axes in area processui adhibentur, quae latis onerationis et exonerationis, massarum inanibus productionem cognoscere possunt.

Machinandi subtilitatem et efficientiam instrumentorum machinarum

1. Runout of the workpiece is within 0.003mm;

2. Accuratius quantitatis 2.0 intra ±0.005mm regitur;

3. Rotunditas operis intra 0.003mm est;

Superficies asperitas <Ra0.4;