GM5X-I 5- axis CNC Molendibilis Machina

Praecipua structura machinae

application scope

Haec machina finem efficit molarem dromonem et terebras, aptas ad processus duris offensionis et celeritatis ferro materiae.

Instrumentum vestibulum et regrinding cycles

Molendina fine Latin: grooving, tergum, rastrum acuere, imum ora acuere, digitizare, regrining.

1. Technical specifications

| № | Content | Necessitas | Numerus | Unitas |

| 1.1 | Workpiece Dimensiones | |||

| 1.1.1 | Longitudo clamping | ≤ | 230 | mm |

| 6.1.2 | diam clamping | inter | 2-20 | mm |

| 6.1.3 | Tandem molendum | ≤ | 150 | mm |

| 6.1.4 | attritio diametri | inter | 0.3-12 | mm |

| 1.2 | attritio Spindle | |||

| 1.2.1 | Coegi genus | accurate | recta coegi | - |

| 1.2.2 | Potestas | rated potentia | 13.6 | kW |

| 1.2.3 | Refrigerium | accurate | Oleum refrigeratum | - |

| 1.2.4 | Celeritas imperium stridor rotae | accurate | Improbus celeritas | - |

| 1.2.5 | Celeritas | inter | 0-1000 | rpm |

| 1.2.6 | Numerum fusum stridor capitibus | accurate | 2 | pcs * |

| 1.3 | rota molere | |||

| 1.3.1 | Diameter | ≤ | 150 | mm |

| 1.3.2 | Maximus numerus stridor rotae per fusum | ≤ | 4 | pcs * |

| 1.3.3 | Rotae attritu diametro fusum | accurate | 25 | mm |

| 1.3.4 | Program imperium coolant copia | accurate | Ita | - |

| 1.3.5 | Numerus coolant nozzles | ≥ | 3 | pcs * |

| 1.4 | Workpiece clamping system | |||

| 1.4.1 | Systema clamping | accurate | Hydraulica, automatice | - |

| 1.4.2 | Clamping collet | accurate | SCHAUBLIN W20 | - |

| 1.4.3 | Coegi genus | accurate | recta coegi | - |

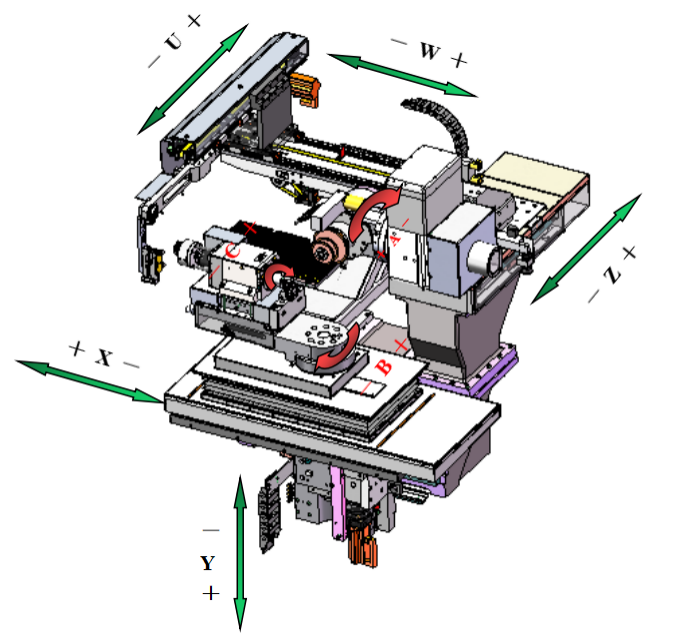

| 1.5 | Axis parametri | |||

| 1.5.1 | Type | accurate | lineari | - |

| 1.5.2 | X-axis peregrinatione | ≤ | 280 | mm |

| 1.5.3 | Z-axis peregrinatione | ≤ | 130 | mm |

| 1.5.4 | Y-axis peregrinatione | ≤ | 230 | mm |

| 1.5.5 | XYZ resolutio axis | accurate | 0.0001 | mm |

| 1.5.6 | XYZ celeritas axis | ≤ | 10 | m/min |

| 1.5.7 | A-axis peregrinatione | ≤ | 360 | gradus |

| 1.5.8 | A-axis resolutio | accurate | 0.0001 | gradus |

| 1.5.9 | A-axis celeritas | ≤ | 300 | rpm |

| 1.5.10 | B-axis peregrinatione | ± | 210 | gradus |

| 1.5.11 | B-axis celeritas | ≤ | 12 | rpm |

| 1.6 | Loading et unloading ratio | |||

| 1.6.1 | Loading et unloading ratio | accurate | Truss genus brachium roboticum | - |

| 1.6.2 | Numerus scutariorum | accurate | 2 | pcs * |

| 1.6.3 | Automatic loading and unloading work-piece diameter | inter | 2-12 | mm |

| 1.6.4 | Automatic loading and unloading work-piece length | ≤ | 40-200 | mm |

| 1.6.5 | Maximus numerus workpieces | ≤ | 300 | pcs * |

| 1.6.6 | Software | accurate | Ita | - |

| 1.7 | Aliae partes | |||

| 1.7.1 | Facultatem ad deprehendere instrumenta workpieces in machina | accurate | Ita | - |

| 1.7.2 | Automatic lubricationis systema centralized | accurate | Ita |

|

| 1.7.3 | Tricolor signum lampadis | accurate | Ita | - |

| 1.8 | Libitum | |||

| 1.8.1 | Oleum caligo separationis armorum | accurate | Libitum | - |

| 1.9 | Imperium | |||

| 1.9.1 | Imperium systema | accurate | NUNC-IM8+ | - |

| 1.9.2 | Operatio tabula | accurate | Tactus screen | - |

| 1.9.3 | Axis digitalis imperium | accurate | Ita | - |

| 1.9.4 | Color ostentationem | accurate | Ita | - |

| 1.9.5 | Propono Location | accurate | 19 | digitis |

| 1.10 | Instrumentum stridor moduli software | |||

| 1.10.1 | Simplex milling caedentes | accurate | Ita | - |

| 1.10.2 | simplex terebras | accurate | Ita | - |

| 1.10.3 | Probe automatic deprehensio modus | accurate | Ita | - |

| 1.11 | Parametri electrica apparatu | |||

| 1.11.1 | Voltage | accurate | 380±10% | V |

| 1.11.2 | Frequentia | accurate | 50±10% | Hz |

| 1.11.3 | Potestas | ≤ | 25 | KW |

| 1.12 | Dimensiones | |||

| 1.12.1 | Longitudo | ≤ | 2 000 | mm |

| 1.12.2 | Latitudo | ≤ | 2 800 | mm |

| 1.12.3 | Altitudo | ≤ | 2 200 | mm |

| 1.12.4 | Qualitas | ≤ | 4 750 | kg |

2. Latin configuration album

| № | Content | Exemplar | Brand | Numerus | ||

| 2.1 | Machina instrumentum | |||||

| 2.1.1 | X-axis configuratione | |||||

| 2.1.1.1 | - virga stupra | nativus | NSK | 1pcs | ||

| 2.1.1.2 | - Rail | 1×MR25-A2-760-20-20-G2-V2+BRK+SOSPL | SCHNEEBERGER | 2pcs | ||

| 2.1.2 | Y-axis configuratione | |||||

| 2.1.2.1 | - virga stupra | nativus | NSK | 1pcs | ||

| 2.1.2.2 | - Rail | 1×MR35-C2-600-20-20-G2-V2+MRK | SCHNEEBERGER | 2pcs | ||

| 2.1.3 | Z-axis configuratione | |||||

| 2.1.3.1 | - virga stupra | nativus | NSK | 1pcs | ||

| 2.1.3.2 | - Rail | 1×MR25-A2-850-20-20-G2-V2+BRK+SOSPL | SCHNEEBERGER | 2pcs | ||

| 2.1.4 | A-axis configuratione | |||||

| 2.1.4.1 | - Anglus encoder | ECN113 | HEIDENHAIN | 1pcs | ||

| 2.1.4.2 | - Direct coegi motricium | MSP-1000-2-002-158 | HIWIN | 1pcs | ||

| 2.1.5 | B-axis turntable | nativus | GuTian | 1pcs | ||

| 2.1.6 | Magnes permanens duplex caput fusum electricum | Ratum potentia 7.1KW | Chuangyun | I PCs | ||

| 2.1.7 | Tres axis truss manipulator | - | Chuangyun | 1pcs | ||

| 2.1.8 | Tray | 148-LP-D4 | Chuangyun | 2pcs | ||

| 2.1.9 | Tray | 148-LP-D6 | Chuangyun | 2pcs | ||

| 2.1.10 | Tray | 148-LP-D8 | Chuangyun | 2pcs | ||

| 2.1.11 | Maxilla clamping | D0.5-3.2/D3.0-7.0/D7-13 | Chuangyun | 1set | ||

| 2.1.12 | V-obstructionum summa cura | 3-5) | Chuangyun | 1pcs | ||

| 2.1.13 | V-obstructionum summa cura | 5-7) | Chuangyun | 1pcs | ||

| 2.1.14 | V-obstructionum summa cura | 6-12) | Chuangyun | 1pcs | ||

| 2.1.15 | Collet | D4W20 80-00004) | SCHAUBLIN | 1pcs | ||

| 2.1.16 | Probe | TS150 | HEIDENHAIN | 1pcs | ||

| 2.1.17 | Rota stridor rod(longus) | 119×∅31.75×∅96mm | Chuangyun | 1pcs | ||

| 2.1.18 | Rota virga molere (brevi | 87×∅31.75×∅96mm | Chuangyun | 1pcs | ||

| 2.1.19 | Caeli condiciones | - | YUEDE | 1pcs | ||

| 2.1.20 | Tricolor signum lampadis | DC24V | Schneider | 1pcs | ||

| 2.1.21 | Flometer | SI5000 | IFM | 1pcs | ||

| 2.1.22 | Certa potestate copia eiciam | 15KW | NEWCOM | 1pcs | ||

| 2.1.23 | Electromagneticae valvae group | M4GE280R-CX-E20D-5-3 | CKD | 1set | ||

| 2.1.24 | X, Y, Z-axis automatismi lubricationis systematis | - | Taiwan | 1set | ||

| 2.2 | CNC systema configuratione | |||||

| 2.2.1 | BOXPC | IMPC00S/P1 | Newcon | 1pcs | ||

| 2.2.2 | Virtus filter | AGOFIL024A | NUM' | 1pcs | ||

| 2.2.3 | Virtus filter | AGOFIL001S | NUM' | 1pcs | ||

| 2.2.4 | Resistentia | AGORES008 | NUM' | 1pcs | ||

| 2.2.5 | Ratio principalis potentia copia | MDLL3015N00AN0I | NUM' | 1pcs | ||

| 2.2.6 | Servo exactoris | MDLUX021B1CAN0I | NUM' | 4pcs | ||

| 2.2.7 | B-axis servo motricium | ZLS1002-H60-D3M1-NNSB-D16E40 | NUM' | 1pcs | ||

| 2.2.8 | A-axis motricium | MSP-1000-2-002-158 | NUM' | 1pcs | ||

| 2.2.9 | Y axis servo motricium | ZLS1454-H30-DCM1-SNSB-D24E50 | NUM' | 1pcs | ||

| 2.2.10 | X/Z-axis servo motor | ZLS1153-H30-D3M1-NNSB-D19E40 | NUM' | 2pcs | ||

| 2.2.11 | II / W axis servo exactoris | ZLS0754-H60-D2M1-SNSB-D14E30 | NUM' | 2pcs | ||

| 2.2.12 | V-axis servo motori | ZLS0754-H60-D2M1-SNSB-D14E30 | NUM' | 1pcs | ||

| 2.2.13 | Coupler | EX-MC | Newcon | 1pcs | ||

| 2.2.14 | Input | EX-210H | Newcon | 2pcs | ||

| 2.2.15 | Output | EX-310H | Newcon | 2pcs | ||

| 2.2.16 | Analog initus moduli | EX-4054 | Newcon | 1pcs | ||

| 2.2.17 | Terminator | EX-TRE01 | Newcon | 1pcs | ||

| 2.2.18 | Operatio tabula | IMOP4106/H | Newcon | 1pcs | ||

| 2.2.19 | NCK | IM8+ | Newcon | 1pcs | ||

| 2.2.20 | NCK | IMSO100006 | Newcon | 1pcs | ||

| 2.2.21 | NCK | IMSO100008 | Newcon | 1pcs | ||

| 2.2.22 | NCK | IMSO100012 | Newcon | 1pcs | ||

| 2.2.23 | NCK | IMPA100586 | Newcon | 1pcs | ||

| 2.2.24 | NCK | IMSO100373 | Newcon | 1pcs | ||

| 2.2.25 | NCK | IMSO100375 | Newcon | 1pcs | ||

| 2.2.26 | NCK | IMSO100335 | Newcon | 1pcs | ||

| 2.2.27 | NCK | IMSO100519 | Newcon | 1pcs | ||

| 2.2.28 | NCK | IMSO100392 | Newcon | 1pcs | ||

| 2.2.29 | NCK | IMSO100331 | Newcon | 1pcs | ||

| 2.2.30 | NCK | IMSO100535 | Newcon | 1pcs | ||

| 2.2.31 | NCK | IMSO100520 | Newcon | 1pcs | ||

| 2.2.32 | NCK | IMSO100560 | Newcon | 1pcs | ||

| 2.3 | Vexillum figura instrumentum stridor software | |||||

| 2.3.1 | Simple milling dromonem | Chuangyun auto-exculta | 1pcs | |||

| 2.3.2 | Simple terebro | Chuangyun auto-exculta | 1pcs | |||

| 2.3.3 | 3D conflictum reprehendo cum 3D machina simulationis | Chuangyun auto-exculta | 1pcs | |||

| 2.3.4 | 3D instrumentum simulationis | Chuangyun auto-exculta | 1pcs | |||

| 2.3.5 | Probe automatic deprehensio | Chuangyun auto-exculta | 1pcs | |||