Quinque-axis millendi et convertendi apparatus FH series

Features

1. Quinque-axis nexus machinis molentis et versatilis mixti machini centrum multiplices functiones in una machina cognosci potest;

conversio verticalis et horizontalis, capax milliendi et convertendi; unum tempus clamping, multi-processus et processus multi-anguli et formandi.

2.Precision est nunquam ending habitus

Structura valde stabilis et summa subtilitas altiorem rigorem etiam emendat, et fundamentalis structura ulterius optimized calculis finitis elementi utens.

3. Securus operatio et precise imperium

Mensa operativa secundum ergonomicos designata potest occurrere idealibus necessitatibus diversis ambitibus laborantibus secundum diversas necessitates, percipere observationem et vigilantiam totius processus processus, optimam operationis operationem consequi et subtilitatem moderaminis curare. In systemate operando constructum continuam administrationem, documenta et visualisationem ordinum, processuum et instrumentorum machinarum notitiarum cognoscere potest, operationem faciliorem et magis in productione producto intentam faciens.

3.1Ergonomic design

Instructus cum 19" multi-tactu ostentationis, multi-anguli rotationis et elevationis, et IPS screen plena visionis, et traditio PC claviaturae iunctio exercitus initus modus

3.2Unified

Exempla omnia unum interfaciendi operating habent, adaptatione additionali non opus

3.3Continuously

Centralized procuratio officium, processus et apparatus notitia

3.4Compatible

Cognoscite compatibilitatem, transmissionem et redintegrationem imaginum in variis formatis

4.Powerful 5-axis universalis capitis milling

Insigniter augeri et emendari impedimentum profile ac rigor

Axis B-axis directae motoris cum DD coegi maius YRT habet ut rigiditatem meliorem sustinentem, quod consequi potest torquem excelsum in nexu statu secando, Heidenhain circulari craticulae instructum et imperium plenae clausulae, ad accuratam pastionem.

5.Turning et milling worktable

DD motricium flectit conversionem et mensam molendinam directe sine catena transmissionis, sine hiatu et dynamica alta, et potest conversionem et molendinalem processus in uno clampando super machinae instrumento perficere. Mensa gyratoria summus oneris capacitatis maximum pondus habet 4T.

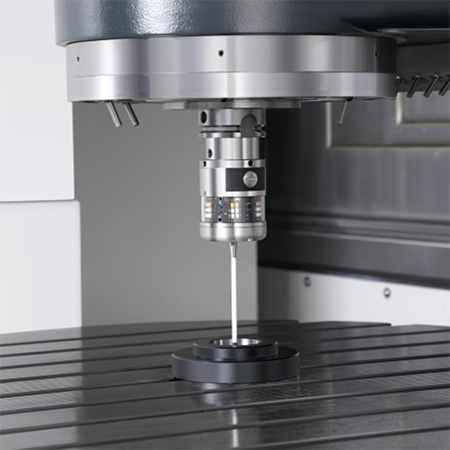

6.Optical tactus felis specillo

OMP60 ultra-parvus 3D felis optical explorationi instructus pro machina fabrica noctis et inspectionis, servat 90% machinae temporis auxiliaris et exiguo rate minuit.

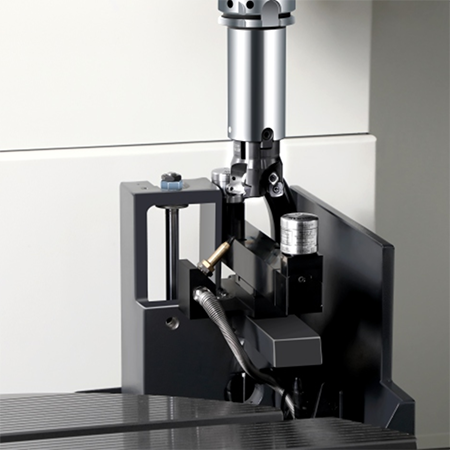

7.Laser instrumentum novorum

Instrumentum ponendi laser instrumentum non-contagium levari et demitti potest, et instrumentum statim in machina collocari potest. Instrumentum recompensationis automatice renovatur, ut accuratius expediatur processus!

Standard Technical Specifications

| Item | FH60P-C | FH80P-C | FH100P-C |

| X / Y / Z axis itinerantur | 600mm*800mm*600mm | 800mm×1050mm×800m | 1000mm×1150mm×1000mm |

| Milling caput centrum ad distantiam ab horizontali operabili | 30mm-630mm | 39mm-839mm | 30mm-1030mm |

| Gyratorius mensam celeritas | 350rpm | 300rpm | 250rpm |

| Worktable magnitudine | 630mm | 880mm | 1100mm |

| Maximilianus. mensa onus | Milling 2000Kg | Milling 3000Kg | Milling 4000Kg |

| vertens 1000Kg | Conversus 1500Kg | Conversus 3000Kg | |

| Milling caput adductius (B axis) | Standard | Standard | Standard |

| Adductius range (0=Vertical/180=Level) | -15° to +180° | -15° to +180° | -15° to +180° |

| B-axis celeritate rated | 50rpm | 50rpm | 50rpm |

| Procul ab vertical fusum nasum ad mensam | 162mm ad 962mm | 162mm ad 962mm | 160mm ad 1160mm |

| Electric fusum Max.speed | 12000rpm | 12000rpm | 10000rpm |

| Potestas (S1-100%/S6-40% DC) | 34/42kW | 34/42kW | 42/58kW |

| Potestas (S1-100%/S6-40% DC) | 32/192Nm | 32/192Nm | 215/350Nm |

| Instrumentum interface | HSK-A63 | HSK-A63 | HSK-A100 |

| Instrumentum magazine facultatem | 40T | 40T | 40T |

| Max.tool diameter/length/weight | Ø85mm/300mm/8Kg | Ø85mm/300mm/8Kg | φ135mm/300mm/12Kg |

| Instrumentum mutantur tempus (Tool to tool) | 4s | 4s | 4s |

| EXERCITATIO (Normalizing medium carbonis ferro) | Ø40mm | Ø40mm | 50mm |

| Ictibus (Normalizing medium carbonis ferro) | M24 | M24 | M40 |

| Fusum cereum | 1:10 Taper | 1:10 Taper | 1:10 Taper |

| Celeri percurre | 40m/min | 40m/min | 40m/min |

| X / Y / Z accurate positioning | 0.006mr | 0.006mr | 0.006mm |

| X / Y / Z repeat positioning accuracy | 0.004mm | 0.004mm | 0.004mm |

| B/C positioning aouraoy | 8'' | 8'' | 8'' |

| B/C repeat positioning acouraoy | 4'' | 4'' | 4'' |

| Infrared specillum | Renishaw OMP60 | Renishaw OMP60 | Renishaw OMP60 |

| Quoque occasu METIOR (Quoque mensuræ in machining area) | Renishaw NC4F230 | Renishaw NC4F230 | Renishaw NC4F230 |

| Machina altitudo (Latin apparatus) | 3350mm | 3350mm | 3650mm |

| Agmen occupatum area (L W) | 4800mmx2930mm | 4800mmx2930mm | 5170mmx3340mm |

| Instrumentum magazine occupatur area (L * W) | 1710mmx1350mm | 1710mmx1350mm | 1915mmx1400mm |

| TRADUCTOR chip regio occupata (L W) | 3070mmx1065mm | 3070mmx1065mm | 3120mmx1065mm |

| Aqua tristique aream occupavit (L * W) | 1785mmx1355mm | 1785mmx1355mm | 1785mmx1355mm |

| Omni spatio apparatus occupatur (exclusis piscinae aquae) (L*W) | 5610mmx3600mm | 5610mmx3600mm | 5000mmx3750mm |

| Apparatus pondus | 20000Kg | 20000Kg | 30000Kg |

| Imperium systema | Siemens 840Ds | siemens840Ds | siemens840Ds |